The Problem

USI’s reputation for Technical Support, Training & Trouble Shooting, had a fellow SEMPPES’s Member (South Eastern Michigan Power Plant Society) recommend USI to this Power Plant that needed help with a new acid resistant lining due to

pitting corrosion from chemical attack, as

the previous lining system had reached end

of life. The first step was determining if the wall thickness was adequate for the relining by doing a UT thickness testing grid.

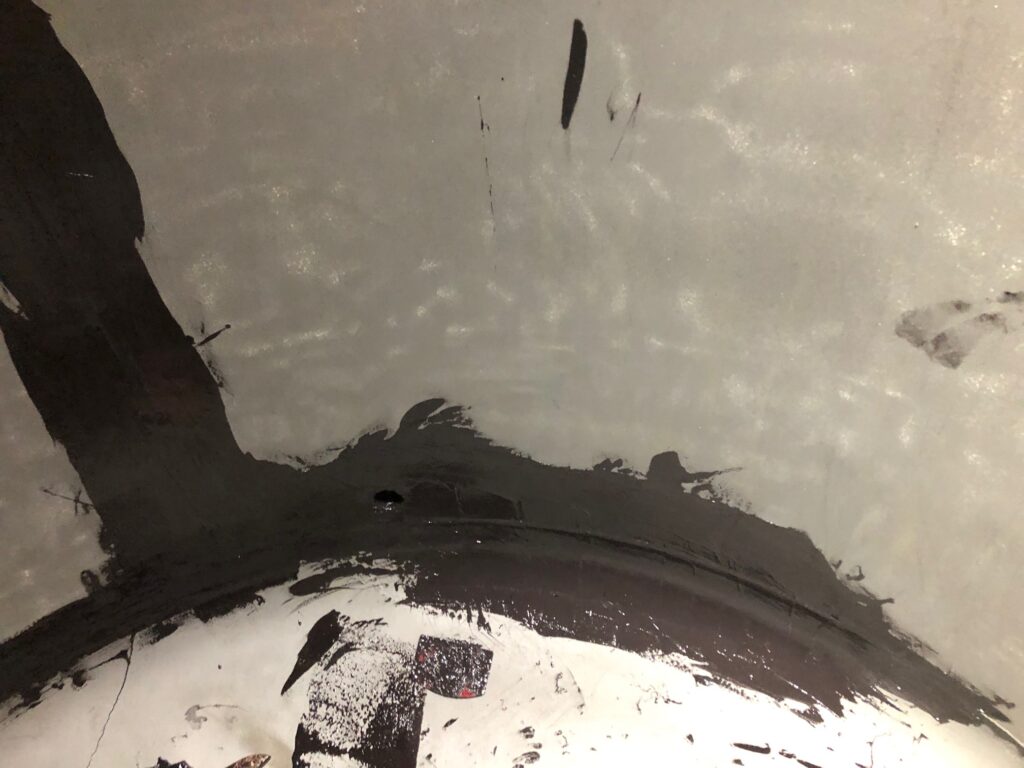

Substrate

The Solution

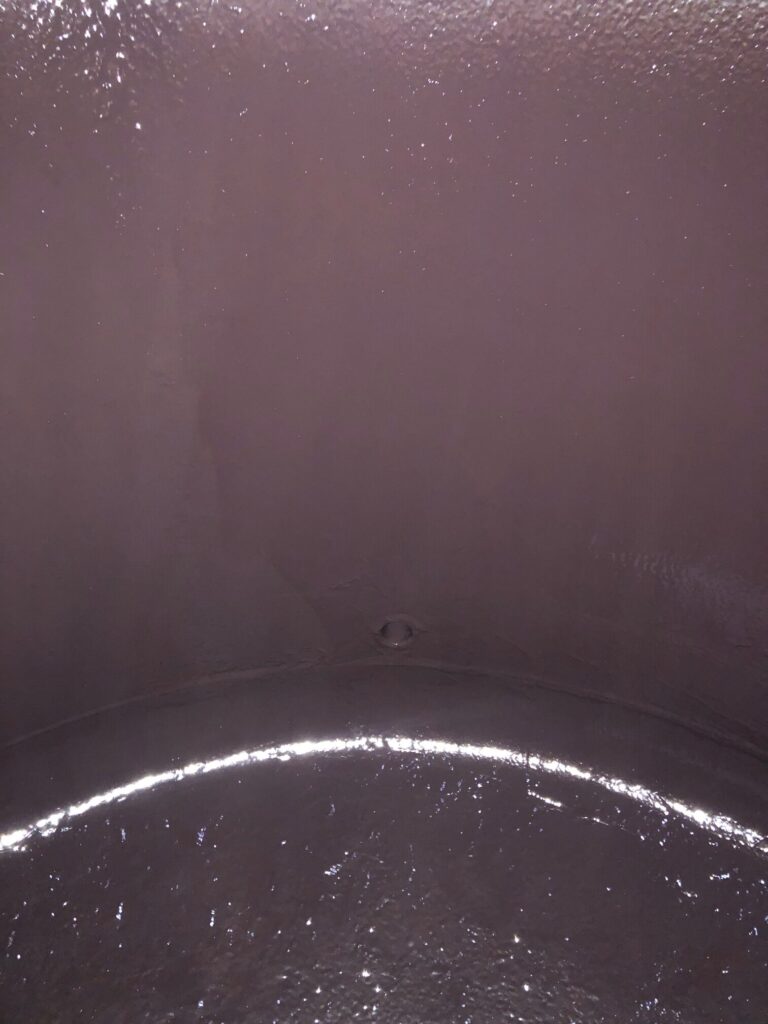

The USI Team started with containing the area by tenting, and then blasted the surfaces of the tank to prepare it for relining. Once the surfaces were properly prepared to NACE #2/SSPC-SP-10 Near White Metal with 2 ½ to 4 mil anchor pattern, Resimac Resimetal 101 Metal Repair Paste was applied to fill in where pitted loss had occurred. Lastly, two coats of Resimac Resichem 511 UCEN, designed for 98% Sulfuric Acid with continuous immersion service, was applied to give a strong, lasting relining to solve the chemical and deterioration problem.

UPDATE:

Ed Going who retired this past October

says, “The repair went well. Good job.

Quality work.” And that it was still in

service as of October 2024.

Jason Shea, Operation Manager and

interim plant manager also said, “It was a

quality job, and still in service.” As of today,

January 7th, 2025.