The Problem

In the industrial sector, conveyor belts are essential for efficient operations. However, they are prone to tears and rips, which can cause significant production delays and financial losses. Replacing a conveyor belt is not only costly but also time-consuming. A quarry facing this issue needed a solution that would allow for immediate repair of the damaged area with minimal disruption and a swift return to service.

The Substrate

The conveyor belt in question was made of rubber, a common material for such applications due to its durability and flexibility. However, rubber can still suffer from wear and tear, especially in harsh industrial environments like quarries.

The Solution

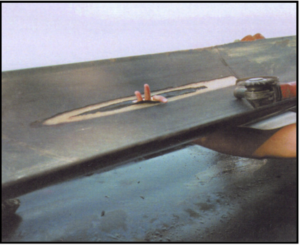

For a quick and effective repair of the worn and damaged conveyor belt, Resiflex products were chosen. Specifically, Resiflex 406 was utilized for its fast-curing properties and ability to provide a flexible yet strong repair solution. The process began with thoroughly cleaning the damaged area of the conveyor belt. Then, Resiflex 402 Multi-Surface Primer was applied to prepare the surface for the repair. The conveyor belt’s reinforcement had worn away, necessitating the application of two layers of Reinforcement Mesh 808 tape, which were embedded into the Resiflex 406. This ensured a robust repair by completely encapsulating the damaged area.

First the surface was cleaned and then primed with Resiflex 402. The reinforcement on the belt had worn away, and two layers of Reinforcement Mesh 808 tape were embedded into the Resiflex 406 and completely encapsulated. The damaged area was then totally repaired.

The customer was delighted at the speed of the repair and massive savings that it has provided the company.

Products Used

- Resiflex 402 Multi-Surface Primer: Prepared the rubber surface for the subsequent application of repair materials.

- Resiflex 406 GP 85 Putty: A fast-curing paste that provided a durable and flexible repair to the rubber surface.

- Resimac Reinforcement Mesh 808: Used to reinforce the repair area, ensuring durability and longevity.

For innovative and efficient solutions to your conveyor belt problems, contact our experts today for a quote. Partner with us for your conveyor repair needs and ensure a swift return to full operational capacity with minimal downtime.