Case Studies

For over 20 years, USI has provided protective coatings and corrosion prevention products proven to protect our nations most critical infrastructure and industrial machinery. Along the way we have documented many projects and pain points we have been able to help our partners repair, protect and upgrade.

Most Recent Articles

Roof on WWTP Building

The Problem

This WWTP was seeing extensive corrosion with their infrastructure. The corrosion was so advanced that it was causing the roof to leak. The facility was located near a nice-looking metro area, they were wanting to upgrade their image to keep their neighbors happy

The Substrate

Steel

The Solution

Abrasive blasting was used to remove the rust. Maxon CRS acts as a corrosion retardant system that penetrates the steel, 20+ mils, so it goes in the metal not on the metal. A viscoelastic sealant was used to seal the joints along with Viscotaq EZ Wrap to create a flexible surface to stop leaking. To make everything look a pleasing two coats of Resichem 555 Resinox. Resinox was spray applied for future corrosion prevention.

Products Used

Resichem 555 Resinox

Maxon CRS

Viscotaq EZ Wrap

Bridge Protection

The Problem

Weathered Steel also known as ASTM A-588, ASTM A-242, or Cor-Ten works well in many environments, and gives structures a rustic look. However, in areas with lots of salt water or low lying areas near rivers or heavy fog, there are some challenges and the structures continue to rust. This major Metropolitan Park authority was looking at extensive sand or grit blasting cost, heavy labor and environmental containment cost,and was in search of solution.

The Substrate

Steel

The Solution

Unconventional Solutions was able to minimize the surface preparation and lower the labor and preparation cost while still offering a long term solution. We recommended RESICHEM 555 Resinox for the entire structure. This flexible acrylic system offered tremendous cost savings and the cash tight metro park was able to do two bridges instead of just one with the surface preparation savings.

Below is a photo 10+ years later in 2021!

Products Used

Gutter Protection

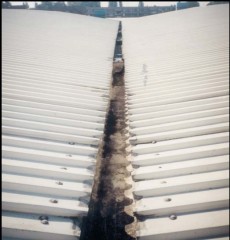

The Problem

The roof of this building of a worldwide supplier of automotive and building control systems, has two 177ft. long box gutters. The client required a long-term high performance protection system, which would waterproof and weatherproof the gutters.

The Substrate

Metal

The Solution

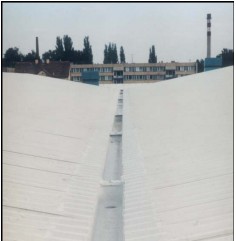

The reinforced Resimac ResiChem 550 WR Membrane system was recommended for this application based on the fact that it is totally unaffected by ponding water or permanent immersion conditions. The surface of the box gutters was prepared in accordance with the ResiChem 550 WR Membrane system recommendation ensuring the substrate was clean, dry and free from contamination. It was then primed with Resimac ResiChem 506 AluPrime prior to the application of the ResiChem 550 WR Membrane system. This comprised one coat of Resimac ResiChem 550 WR Membrane into which the Resimac Chop Strand Mat was embedded, followed by a second coat of Resimac ResiChem 550 WR Membrane.

Products Used

Resimac ResiChem 550 WR Membrane

Resimac ResiChem 506 AluPrime

Resimac Chop Strand Mat